Geekworm Smart

Fan and Power Expansion Board

Note: Your fan HAT may or may not be a “Geekworm” as they

seem to be made under different names. I read many articles that state that the Raspberry Pi does

not require a cooling fan as the board is designed to handle temperatures in

the 70ºC range and will throttle the CPU/GPU to reduce the heat if required.

But, personally, I still like to use heat sinks and fans and keep the

temperature down even if it won’t do any actual damage. Besides, it was a

good project to refresh my math skills.

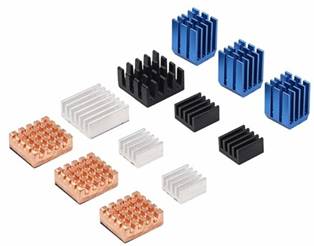

I will assume that at this point you should have some

basic knowledge about heatsinks and cases. There are many different types of

heatsinks available to you should you decide to use one. Not only do they

come made of different materials (copper, aluminum, etc) but they come in

different sizes. The number, size and type is up to you to research and also

depends on the model of your Raspberry Pi. Keep in mind that if you are going

to install a heatsink then the placement of your fan will also be important

and the available space for these components must be considered. If you are

using a case then it may or may not have slots or mounting mounts for a fan.

You may have to make some modifications to the case yourself. Some people

claim that the method you use to attach the heatsink to the chip can actually

increase the temperature. I will let you do your own research, but the short

version is that you should use a proper thermal adhesive if you use a

heatsink.

I spent many hours reading all about fans and various ways

to control them, or not. Some solutions are quite simple and are literally a

5V 0.2A fan plugged into the GPIO pins for +5V and GND. There are even water

cooled and mineral oil cooled solutions. I won’t go into those.

Basic 5V fan. This option has some obvious benefits, and

obvious drawbacks. Benefit: can’t get much simpler. Drawbacks: No control.

The fan runs at maximum speed all the time. These little fans can be quite

noisy at high speed so this is not ideal if you plan or being anywhere near

it. You could splice an on/off switch into the wiring and mount it in your

case to provide some basic control. Some people suggest that using a 12V fan

and supplying only 5V will result in a quieter solution as the fan will not

run at full speed. However, the fan may not run at all either, depending on

your power supply and the fan.

The Raspberry Pi can provide something called Pulse Width

Modulation, or PWM. Essentially this is a way to send a signal to your device

(fan, LED, etc) that quickly pulses the power on and off to allow you to

control the “strength” in a sense. This can be used to control the brightness

of an LED or the speed of a fan. This diagram shows the use of a transistor

and resistor to safely provide speed control to the fan. There are many other

examples using various fans, transistors, resistors and other components but

the basic principal is the same. By adding a couple of basic components, you

end up with a simple and inexpensive hardware solution. But, that is only

half of the overall solution. You need a software component (script) to set /

control the PWM value to turn the fan on, off, or to a specific speed. More

on that later.

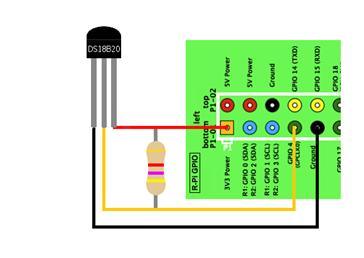

By adding a temperature sensor such as the DS1820, DHT11,

DHT22 or one of many others, you can monitor the temperature of a specific component

or generally within the case. With a script you can then set an appropriate

fan speed to balance noise levels with the temperature control. Note that the Raspberry Pi does allow you to monitor the

CPU and GPU temperatures WITHOUT adding any additional sensors.

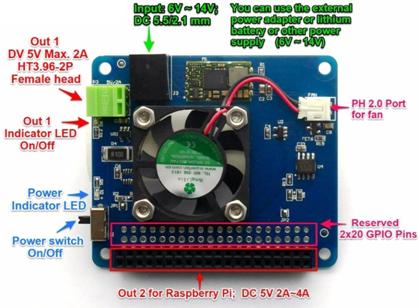

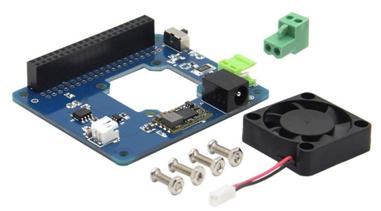

This HAT comes as a simple kit and all that is really required

is to mount the fan using the bolts. All the parts shown here came with the

kit I purchased. Because I have some relatively tall heatsinks that I like to

use, I chose to install the fan on the opposite side of the HAT than it is

typically mounted. To facilitate the wiring I cut a small slot into the

unused portion of the PCB on the side of the opening for fan near the fan

power connector. I also had to trim some of the power switch plastic slider

as it was too long by about 1mm to fit in my case.

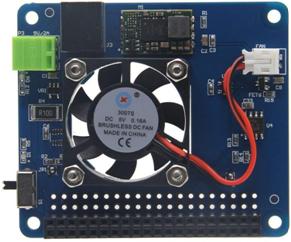

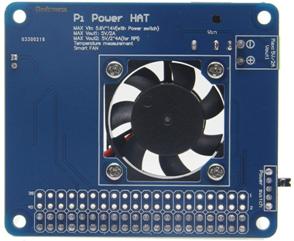

The full version of this kit includes a “case”, which is

really just a couple plastic plates and brass standoffs. This image shows the

“standard” mounting of the fan and placement on the GPIO pins. More images and sample code can be found on this web site: http://www.raspberrypiwiki.com/index.php/Smart_Fan_and_Power_Expansion_Board The last bit that I will discuss briefly in relation to

this HAT compared to some others is that it does NOT have a real time clock

(RTC) module or battery. At one point there was a product called the

PiCoolFan which seemed ideal. It was a small board (see image) that included

a temperature sensor, PWM fan control and RTC. I have as yet been unable to

determine its suitability for use with the RPi3B+ and it seems it may have

been replaced by another product which does not include a RTC. In any case,

one thing I like about the Pi Power Hat is that it includes access to the

GPIO pins so I could add my own RTC quite easily. Enough about the hardware, let’s get scripting! Almost all the PWM fan control scripts I could find were

pretty basic. At best, most seemed to provide an incremental speed control

based on temperature ranges and fixed increments. I was after something

better than 0, 25, 50 75 or 100% fan speed control and something more

flexible and dynamic. As an example, most scripts would use the logic

equivalent to: If the temperature is above 40 but lower than 50 then set the

fan speed to 25%. Using these scripts as a starting point I wrote my own

script that should be easily configurable to match most installations. The script uses a couple different methods to query the

Raspberry Pi internal CPU temperature sensor. The modular design of the

script allows for the easy addition of other methods such as querying I2C

sensors (such as the one included on this HAT) although I consider the

onboard CPU temperature to be the one I am most interested in. In the configuration

settings within the script you can set the minimum temperature at which you

want the fan to start thus allowing the fan to be off, if desired, at lower

temperatures so that there is no noise. You also configure a temperature

above which the fan will run at its full capacity to provide maximum cooling. A calibration script should be run on each Raspberry Pi

with each specific fan to determine the minimum value for the PWM at which

the fan will actually begin to turn (although you could configure a reasonable

“guess” as this is only used as a base starting point). A maximum PWM value

can also be configured so that the fan will max out at 100% or whatever value

you set thus enabling you set only run at a speed at which the fan noise is

appropriate for you. The script will use the configured temperature range and

the configured PWM values to automatically determine the fan speed. Actual

real-time percentages are used rather than a fixed scale. For example, if it

is determined that the actual temperature is 15% of the way between the

minimum and maximum values, then the fan will be set to run at 15% of the

maximum rate configured in the script. While this may be overkill, it was relatively simple to

calculate a dynamic fan speed based on the temperature. The time between each sampling of the current temperature

can be configured as well. As the script runs under Python, which carries

some overhead, you don’t want to sample too often or the script itself will

cause the CPU temperature to rise. Generally speaking, sampling the

temperature once every 3-5 seconds is often enough without putting additional

load on the CPU. In many cases sampling every 10 or 30 seconds would even be

sufficient. The script is designed to run as a background task but

there are 2 diagnostic options that can be enabled. A real-time output can be

displayed to the console (telnet or SSH shell) and optionally be redirect

through a standard pipe to a file for logging purposes. Also, the last loop

iteration can be enabled to be logged to a file making it easy to see at a

glance though shell access, a web site or file share what the last

temperature and fan settings were. These optional diagnostics can be

individually disabled or enabled. |

Update September 28th, 2018

Ok, so one thing that I

didn’t like was the issue that I have always liked having a Real Time Clock

(RTC) installed. In the past I’ve tried them all, DS1302, DS1307, etc and made

lots of little add-on boards with batteries. I ended buying a bunch of the

DS3231 modules as they were small, simple to install and used a super-cap to

maintain the time.

The issue then became

installation. The fan HAT obviously blocked the GPIO header. Idea! Remove the

header from the DS3231 module and use the blank header on the fan HAT to

install the module.

I’ve also been playing with

the temperature sensor on the HAT. It turns out it is a LM75 chip (8-pin chip

just above the fan power connector). This is great as both the LM75 and the

DS3231 use the I2C bus but default to different addresses. Also, a quick mention

that the on-off switch does work, if you use the power connector on the HAT.

Slide it towards the GPIO header to turn on the power, and slide it towards the

middle of the HAT to turn it off. I couldn’t find this posted anywhere and

although fairly obvious, I wanted to make mention of it. You may also notice that I installed the fan on the opposite side than intended. I did this to make more room for the heatsinks and RTC module. There is just enough space in the case I used for a slim fan.

More details and examples of

how to use the LM75 will be posted in the sample scripts.